Harvard Apparatus

New Product Development Engineer

New Product Development Co-op

January 2016 - June 2016

My main role at Harvard Apparatus was making changes and building custom products based on customer requests. This included designing, modeling, prototyping, ordering from suppliers, testing, redesigning if necessary, manufacturing, and shipping to customers.

My role also included first article inspections and testing, resolving issues with RMA parts, and recording and evaluating data for validation reports.

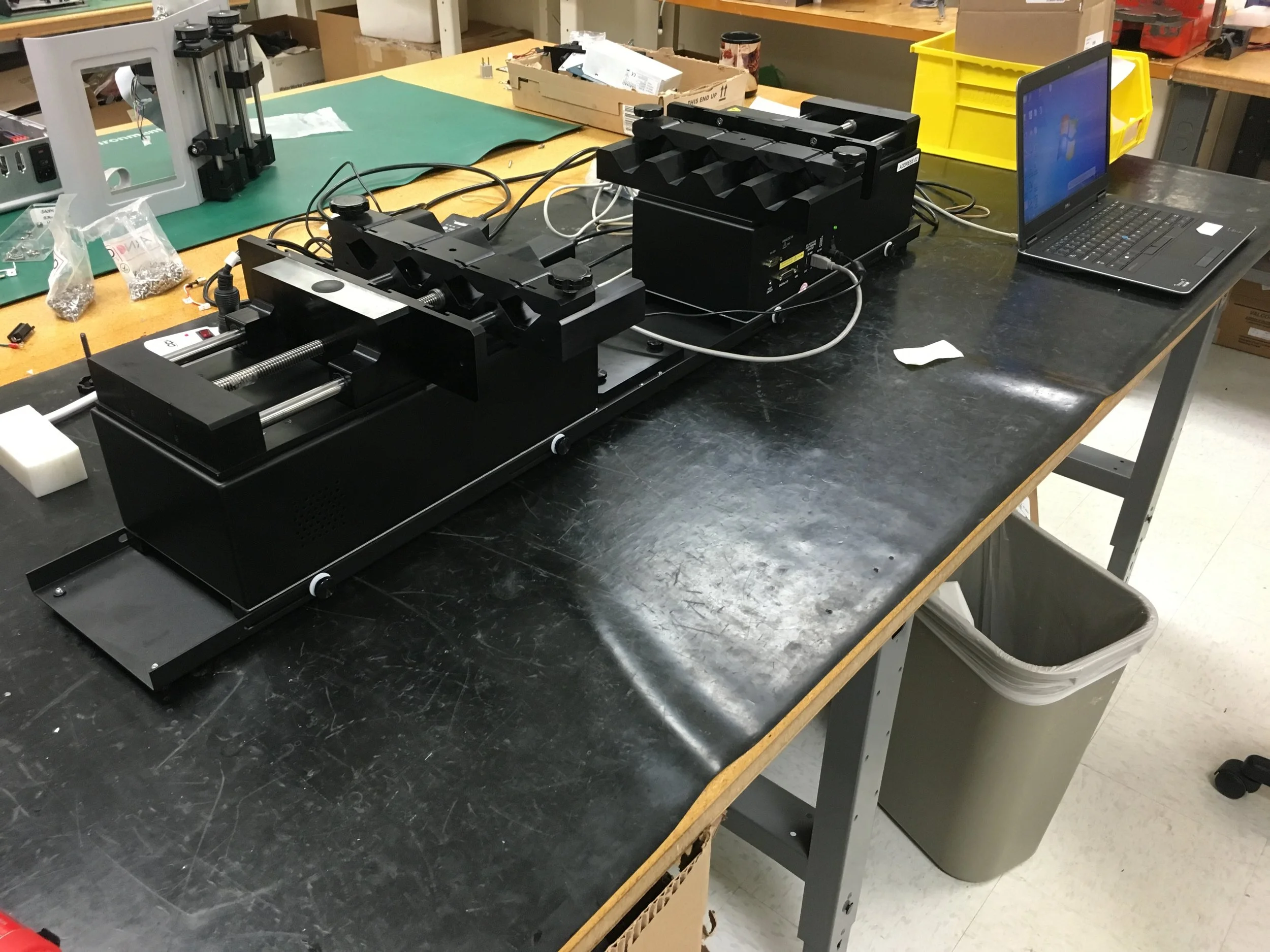

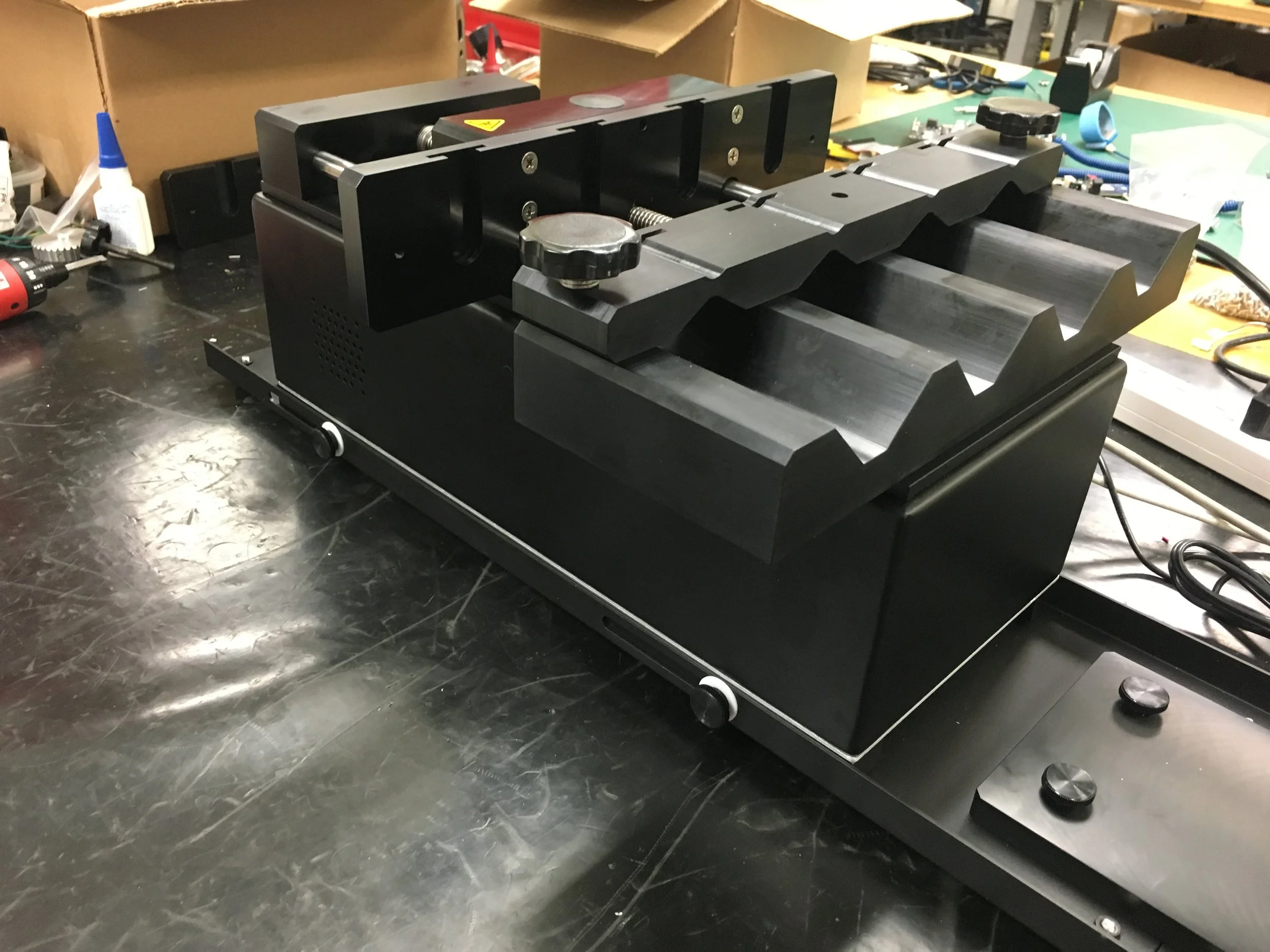

Double PHD Ultra XF Custom Product

For this product, a customer required two high-force XF pumps to be mounted on a system where two syringe pumps needed to be rigidly affixed to something in order to remove the load from the syringes connected across the gap between the pumps.

This project was completely under my command and I had the responsibility of creating a product that would fulfill the need for the customer.

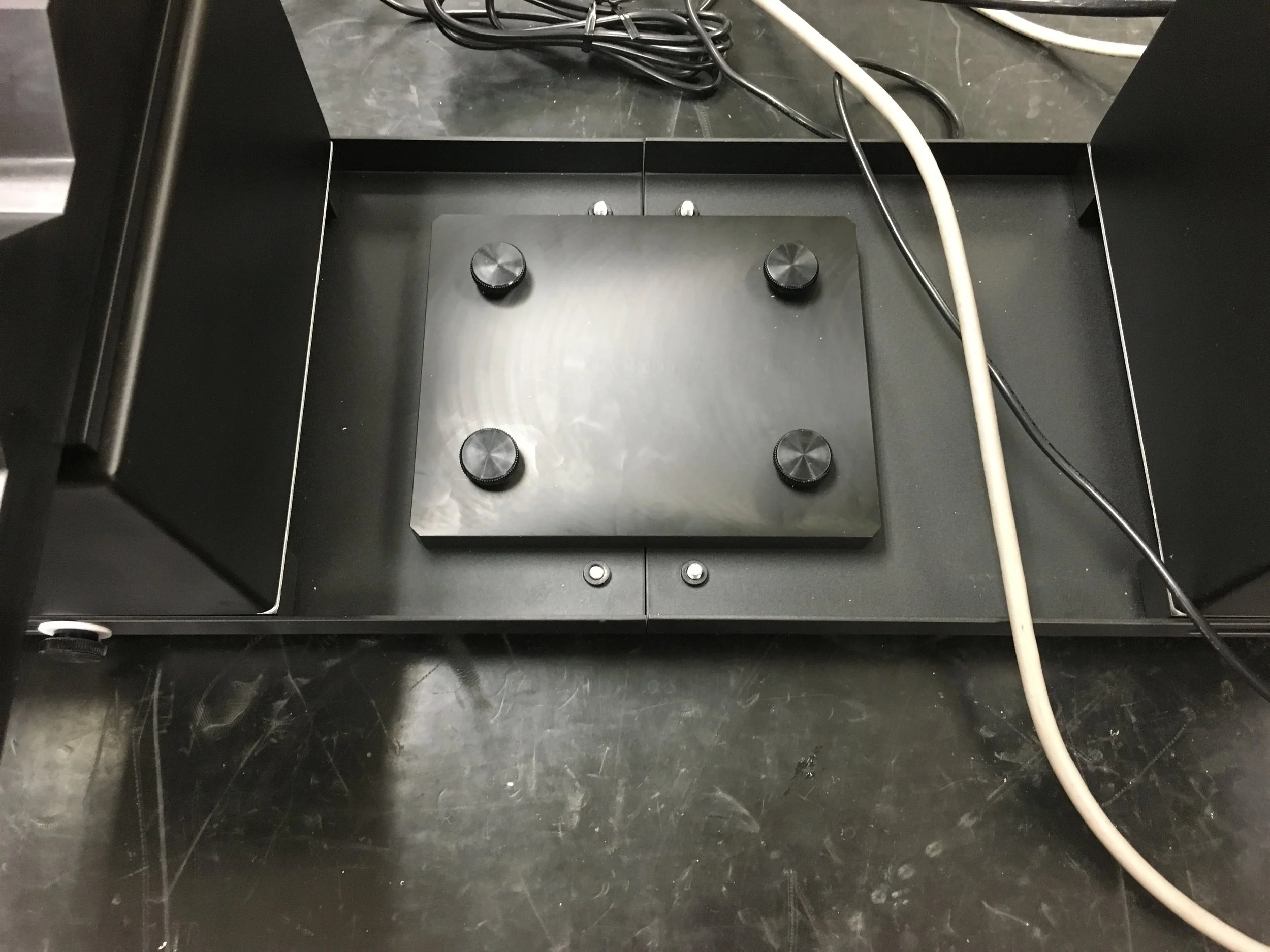

The new baseplate that I designed had to be lightweight enough to be shipped and handled easily while still being able to support the weight of the pump and the force of the pushing. this was achieved using steel with 90 degree bends at the corner with steel thick enough to withstand said forces.

This joining plate was designed so that the rail system that the pumps were on could be disconnected and shipped easily. This joining plate would also be going under significant load, since the pumps are capable of exerting 1000 pounds of force in either direction. This plate needed to be sturdy, rigid, and easy to assemble.

I designed custom guide rails to replace the rubber feet that were standard on this pump. These external rails matched the slots along the edge on the trays where thumb screws could be used for assembly.

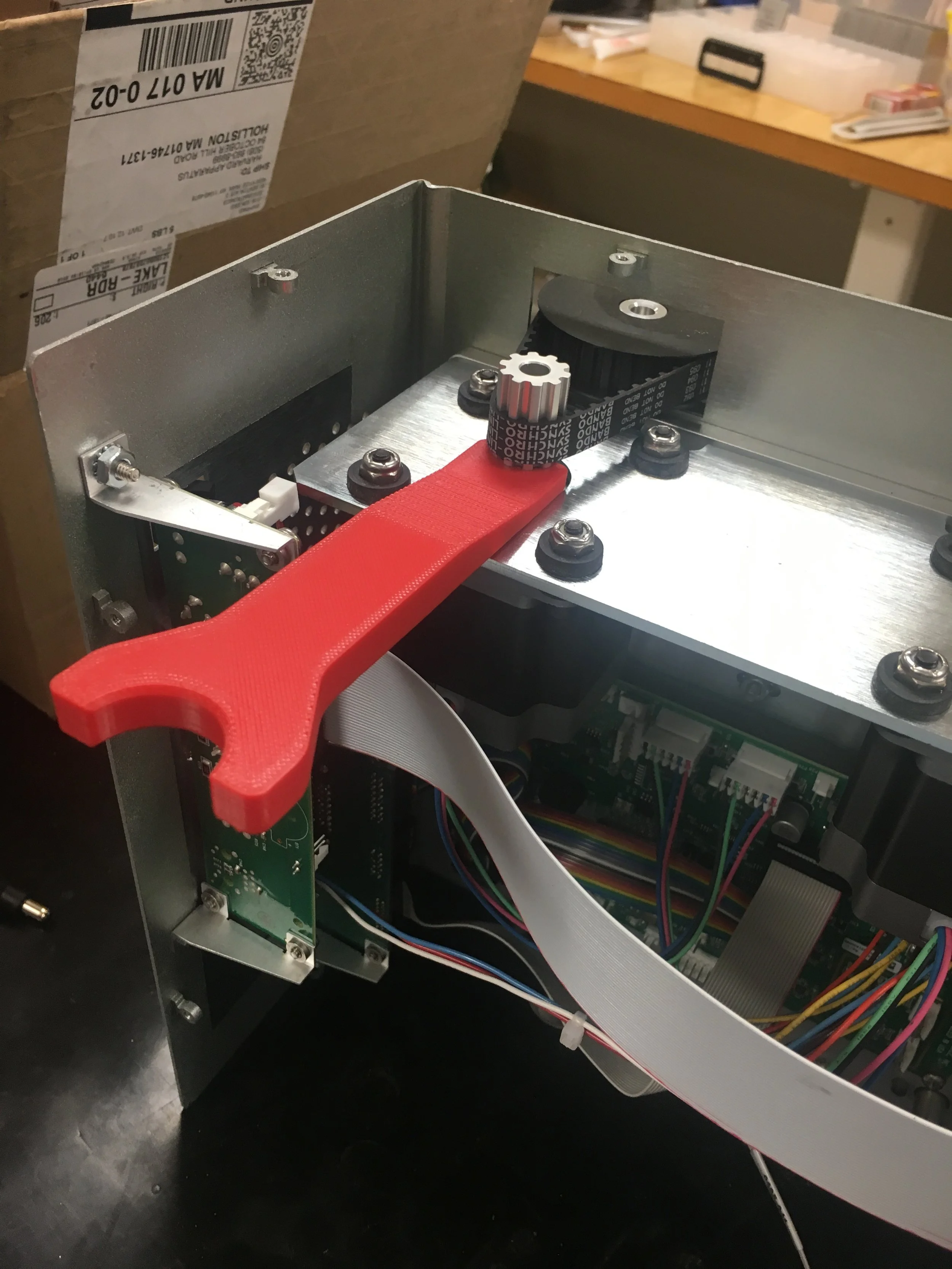

Spring Steel Redesign & Installation Jig

The object in the photograph is a rotational to linear motion convertor. a DC step motor would be inserted into the silver disk, and when that rotated, the bar would pushed back and forth.

This project was a two-fold and involved redesigning the band of steel that wraps around the silver disk. The band was too thin of steel and the edges had a tendency to catch on each other, and the bands would break.

The new redesigned spring with correct spacing and thicker spring steel worked much better in testing, but were nearly impossible to install. I designed and printed the red jig with the metal peg in it in order to facilitate installation. The black bar is spring-loaded in order to keep tension, so the jig holds this tension while the installer has a much easier time inserting the spring steel.

Drive Gear Spacing Tool

On this syringe pump, technicians were having difficulty spacing the drive gears properly. Belts were over-tensioned or out of alignment. This 3D printed tool made it so that the gears could be installed with ease, instead of using calipers or trying to eyeball it. It was a side project done to help streamline manufacturing.

Linear Encoder Bracket

This linear encoder was difficult to calibrate, so I designed a new bracket that allowed for on-the-fly adjustment for easy installation for an optical linear encoder.